When you work around heavy equipment, everything should work safely and efficiently, helping you perform tasks in different environments. The brakes are among the most important components, but they can degrade and fail over time. When you look for signs it’s time to service your heavy equipment wet disk brakes, you can maintain them and keep your mining operation safe and productive.

Reduced Stopping Power

The first and most obvious sign that your heavy-equipment brakes need servicing is reduced stopping power. If it takes longer for your machine to come to a complete stop or you have to push harder on the brake pedal, things aren’t working as they should. Whether it’s a worn-down brake discs or low fluid levels, you need to take care of these issues quickly. Keeping your brakes in top condition maintains stopping power and control over your heavy equipment.

Burning Smell

Another sign you need to service your heavy equipment brakes is an intense burning odor when operating the equipment. This stench could indicate a serious malfunction or overheating issue that requires your immediate attention. Burning smells originating from the braking systems are commonly caused by overheating of the brake discs and, if left unrepaired, will cause brake failure and can eventually combust. This can lead to additional unnecessary damage to your equipment.

Vibrations When Braking

Vibrations or pulsations are other common signs of brake problems in heavy machinery. They usually signify warped components, which you should replace or repair to get your equipment performing efficiently and safely again. Heat buildup and constant braking can cause these warping issues. You can avoid warping by conducting regular inspections, saving you time and money on repairs.

High Heat

High heat is another sign to look out for. When the brakes generate excessive heat, you’ll notice reduced braking efficiency or damage to the entire braking system over time. This could result from prolonged use without adequate cooling periods or issues with the brake fluid, like contaminants or low levels.

Whatever the cause, neglecting high heat can compromise your safety and lead to brake failure and costly repairs. Thankfully, regular maintenance and inspections of your brake system can help you spot and prevent these issues from happening and hurting your mining equipment further.

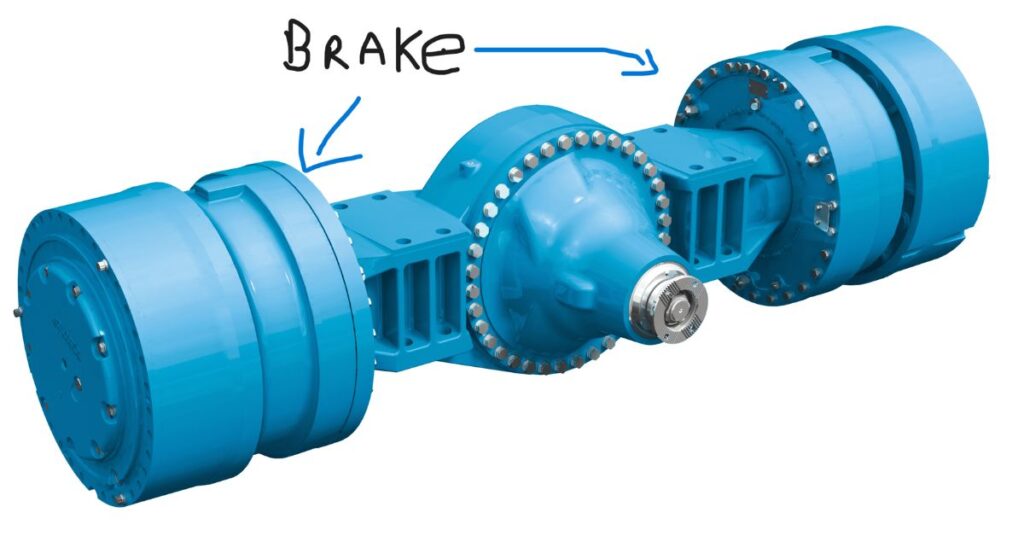

Maintaining and servicing your heavy equipment brakes is important, so watch out for these warning signs. Regularly inspect and service your brakes, and if necessary, replace them completely. With Bull Powertrain, replacing your brakes with high-quality off-highway OEM brakes is easy.