You’re likely familiar with powerful off-highway equipment and machines since they make up a big role in your industry, whether you work in the mining industry, construction, or agriculture. Off-highway equipment encompasses a range of heavy machinery, including bulldozers, excavators, and much more.

This equipment is the backbone of your industry. Therefore, you must know the complete background of off-highway equipment. With this knowledge, you can better understand the diverse uses and applications of this equipment and how technological advancements are transforming them into even more impressive machines.

Evolution of Off-Highway Equipment

While off-highway equipment tends to look the same from an outsider’s perspective, they constitute many machines. Different industries must use these different machines for their uniqueness; in the last few decades, this equipment has evolved a lot. However, you can see the effect of off-highway equipment going back all the way to ancient civilizations.

Ancient Civilizations

People worked with simple machines to accomplish essential tasks such as farming, construction, and transport. However, in addition to simple machines, they used other basic tools such as:

- Levers

- Pulleys

- Wedges

These early innovations laid the groundwork for future developments, and they demonstrate the ingenuity of our ancestors, who sought ways to ease manual labor and improve productivity.

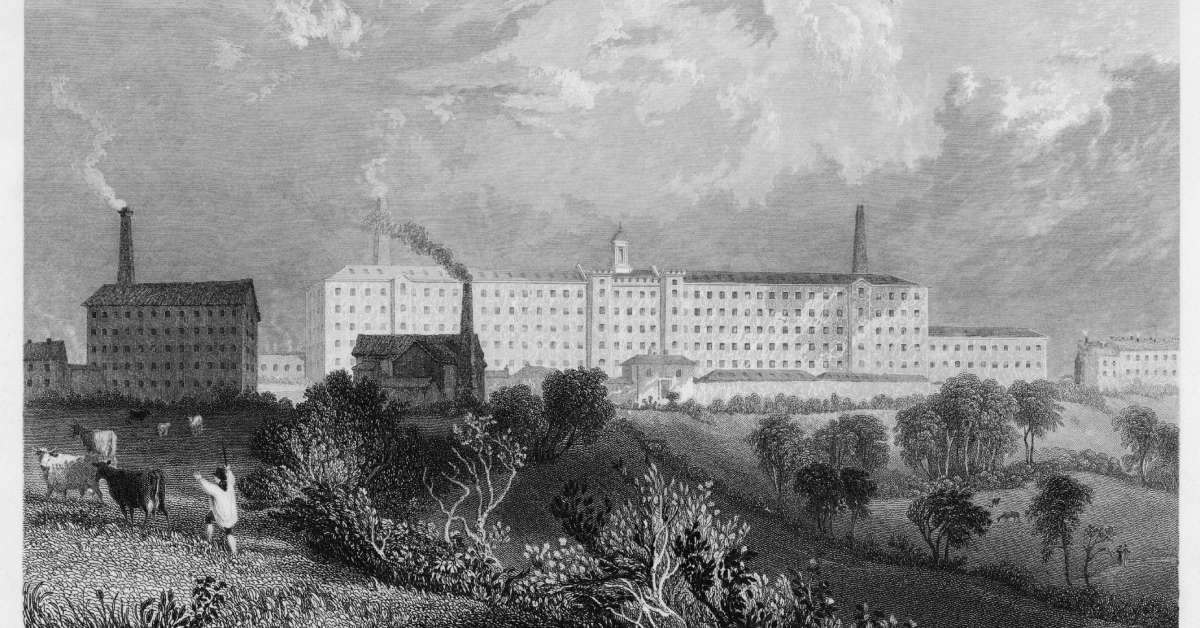

The Industrial Revolution

The Industrial Revolution, which began in the 18th century, marked a significant turning point in the evolution of off-highway equipment. The invention of steam-powered machines such as tractors and excavators revolutionized the execution of heavy tasks by increasing efficiency and reducing the need for human labor. This period also saw the development of steam shovels and locomotives, which transformed industries, laying the foundation for modern infrastructure and operations.

Gasoline-Powered Engines

The early 20th century also saw gasoline-powered engines further transform the capabilities of off-highway equipment. These internal combustion engines offered unprecedented power and reliability, making machines more versatile and efficient for earthmoving, logging, and construction tasks.

Hydraulic Systems

In the mid-1900s, people integrated hydraulic systems into off-highway equipment, providing operators with more precise control over machine movements. This advancement simplified more complex tasks such as precise digging and lifting heavy loads. Hydraulic systems also enhanced the versatility of equipment such as bulldozers, excavators, and loaders.

Uses and Applications of Off-Highway Equipment

This off-highway equipment has evolved a lot over the last century or so, but how are people using it today? While numerous industries rely on this high-quality machinery, each tends to take advantage of this equipment in different ways.

Construction

Off-highway equipment is indispensable in construction projects, ranging from building roads to erecting towering skyscrapers. Contractors use machines, such as bulldozers, excavators, and cranes, for a variety of tasks such as:

- Earthmoving

- Lifting

- Material handling

These machines help streamline the construction process, greatly reducing manual labor and increasing efficiency. Bulldozers and excavators, for example, are vital for moving large quantities of soil quickly and precisely, while cranes are better for lifting heavy materials to great heights.

Mining

The mining industry depends on off-highway equipment for essential tasks such as excavation, material transportation, and drilling. These tasks are critical for extracting valuable minerals from the earth. Dump trucks transport large quantities of extracted material from mining sites to processing locations. Loaders also help move materials on site, loading them onto transport vehicles. This equipment is vital in any successful mining operation.

Material Handling

Off-highway equipment, such as forklifts and pallet jacks, are essential for moving materials quickly and efficiently in warehouses and distribution centers, ensuring smooth operations. Forklifts help lift and transport heavy pallets and containers, while pallet jacks allow for the easy movement of goods in tight spaces. This equipment also simplifies the flow of goods, from receiving to shipping, and they also play a key role in inventory management and logistics.

Technological Advancements

Understanding the uses and history of off-highway equipment is important, but what does the future of this equipment look like? There have been numerous technological advancements since off-highway equipment became commonplace, and this push toward technology is showing no signs of stopping any time soon. While some of these pieces of technology are more commonplace in industries today, they are still in their infancy and will only evolve as time goes on.

GPS Technology

Many modern off-highway machines, such as bulldozers and excavators, come with advanced GPS systems. These systems enable precise positioning and automated guidance, which are crucial for tasks such as grading and excavation. This technology significantly enhances productivity and accuracy, ensuring that projects stay on schedule and within budget.

Telematics

Telematics systems are revolutionizing how you manage off-highway equipment. By allowing for remote monitoring and tracking, telematics provide real-time data on critical parameters such as:

- Performance metrics

- Fuel consumption rates

- Maintenance schedules

This information makes it a lot easier to optimize machine usage, reduce operational costs, and minimize downtime due to unexpected mechanical failures.

Autonomous Operation

The introduction of autonomous operation capabilities in some off-highway equipment, such as dump trucks and loaders, marks a significant leap forward in efficiency. These machines can perform certain tasks without human intervention, which is particularly beneficial in challenging environments such as mines. Here, innovation boosts efficiency and enhances safety by keeping operators out of potentially dangerous situations.

Electric or Hybrid Engines

There is an increasing shift toward greener alternatives in off-highway equipment, with electric or hybrid engines becoming more common. These engines significantly reduce emissions and fuel consumption while maintaining the power and reliability required for heavy-duty tasks. Technologies such as hybrid and electric engines reflect a greater commitment to sustainability in the industry.

Advanced Control Systems

Today’s off-highway equipment features sophisticated control systems that provide operators with greater precision and ease of use. Touchscreen interfaces, joystick controls, and ergonomic designs enhance the overall operator experience. These advanced systems improve machine performance and reduce operator fatigue, promoting safer and more effective operations over long periods.

Safety Features

With ongoing technological advancements, off-highway equipment now includes an array of enhanced safety features—for example, collision avoidance technology, backup cameras, and proximity sensors are standard in many machines. These features protect operators and bystanders, mitigating the risk of accidents and injuries. Enhanced safety protocols are also crucial in keeping the worksite free of issues.

This complete background of off-highway equipment has proved that this equipment has evolved significantly from its humble beginnings, becoming an array of powerful machines that multiple industries rely on. These machines have revolutionized the world, from mining to construction and agriculture, but that’s only if they work. Bull Powertrain works with lots of off-highway equipment, so we know how to service them and keep them in top shape. Be sure to work with us at Bull Powertrain whether you need general servicing or something more specific, such as some Kessler off-highway parts!