Heavy-duty machinery operates under extremely demanding conditions. From hauling tons of materials in underground mines to navigating steep inclines on construction sites, load-carrying equipment faces constant stress. One component that keeps load-carrying equipment safe and operational is hydraulic wet brakes.

The braking systems deliver consistent stopping power while withstanding extreme temperatures, moisture, and debris. Understanding how they work and why they matter will benefit operators and maintenance teams.

Load-Carrying Equipment in Industrial Operations

Load-carrying equipment encompasses a wide range of machines that transport materials across challenging terrain. Each type serves a specific purpose in mining, construction, and industrial settings.

Underground Mining Vehicles

Mining vehicles operate in confined spaces; there’s limited ventilation, and temperatures fluctuate frequently. Load-haul-dump (LHD) loaders move ore from excavation sites to collection points. They brake frequently while carrying heavy loads on steep grades. Personnel carriers transport workers through narrow tunnels where reliable braking prevents collisions in low-visibility conditions.

Surface Mining Equipment

Surface mining equipment moves on open-pit sites where haul trucks carry hundreds of tons of material. Off-highway trucks navigate winding roads with elevation changes exceeding 1,000 feet.

Articulated dump trucks handle rough terrain while maintaining stability during sharp turns. These vehicles need braking systems that perform consistently across varying loads and speeds.

Material Handlers

Material handlers include wheel loaders, forklifts, and telehandlers that move supplies and equipment. Wheel loaders scoop materials and transport them short distances. Industrial forklifts operate in warehouses and manufacturing facilities. Telehandlers extend loads to heights where precise control matters. All these machines require responsive braking that allows operators to stop quickly without losing control.

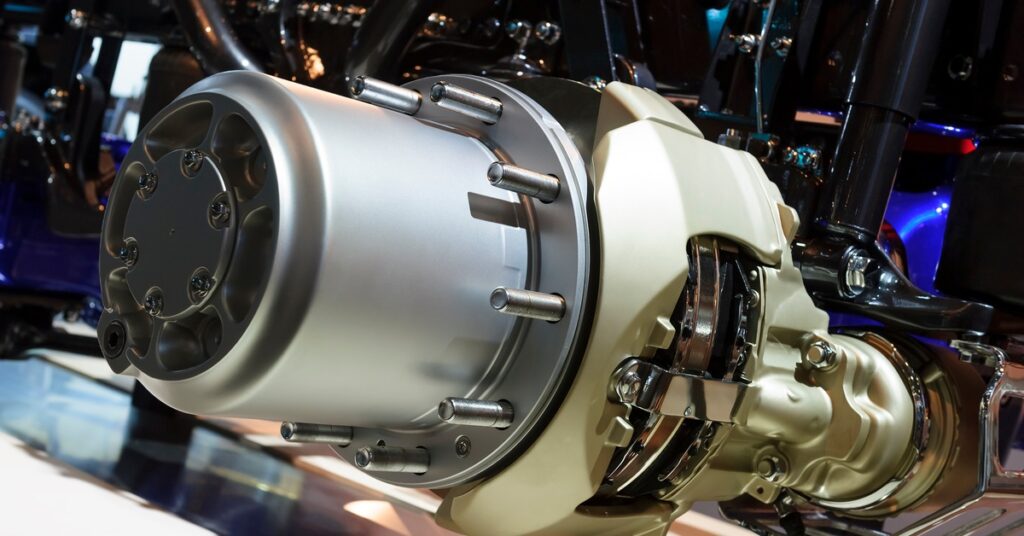

How Hydraulic Wet Brakes Work

Hydraulic wet brakes combine fluid pressure with friction materials submerged in oil. This design differs from dry brakes that rely on air or friction alone.

The system starts with a hydraulic pump that generates pressure when the operator presses the brake pedal. The pressure travels through fluid lines to the brake assembly.

Inside the brake housing, multiple friction discs alternate with steel plates. The friction discs connect to the wheel or axle, while the steel plates attach to the stationary housing.

When hydraulic pressure builds, a piston forces the friction discs and steel plates together. The friction between these components creates resistance that slows the wheel.

Oil surrounds the entire assembly, serving two purposes. First, it cools the components by absorbing heat generated during braking. Second, it lubricates the surfaces to reduce wear. The oil flows continuously, carrying heat away to a cooler or reservoir where it dissipates.

This sealed environment protects internal components from contaminants. Dirt, water, and other debris cannot enter the brake assembly. The oil bath also prevents rust and corrosion that would degrade performance in open brake systems.

Advantages of Hydraulic Wet Brakes

Hydraulic wet brakes offer several benefits that make them suitable for heavy-duty applications:

- Heat dissipation: Oil absorbs and transfers heat away from friction surfaces, preventing brake fade during prolonged use.

- Prolonged component lifespan: Lubrication reduces wear on friction discs and plates, lowering replacement frequency.

- Prevent contamination: Sealed housings keep dirt and moisture out, maintaining consistent performance.

- Smooth operation: Gradual engagement provides controlled stopping without sudden jerks.

- Reduced maintenance: Fewer external components mean less frequent inspections and adjustments.

Brakes That Withstand Rugged Conditions

Mining and construction environments test equipment to its limits. Hydraulic wet brakes excel in these settings because their design addresses common failure points.

Temperature Management

Underground mines reach temperatures exceeding 100 degrees Fahrenheit, and surface operations in hot climates can push ambient temperatures even higher. Friction generates additional heat during braking. Dry brake systems struggle under these conditions, experiencing fade as temperatures rise.

Hydraulic wet brakes maintain stopping power because oil continuously removes heat from friction surfaces. The fluid circulates through coolers that regulate temperature, preventing performance loss.

Moisture Resistance

Moisture resistance matters in wet mining environments because water spray controls dust and natural groundwater in work areas. Average brake systems corrode when exposed to moisture, thereby increasing the chances of inconsistent braking and component failure.

The sealed design of hydraulic wet brakes keeps water out while the oil bath prevents rust on internal parts. This protection extends brake life and maintains reliable performance in humid or wet conditions.

Contamination Defense

Open brake systems allow particles to enter friction zones; they facilitate accelerated wear and unpredictable braking. Hydraulic wet brakes isolate friction components in sealed housings. Oil filters trap any particles that might enter through seals, keeping contamination away from braking surfaces. The design results in fewer unscheduled repairs and consistent stopping power in all conditions.

Load Handling Capacity

Load handling capacity tests brakes when machines carry the maximum weight. A full haul truck weighing 400 tons generates enormous kinetic energy. Converting that energy to heat during braking requires components that can handle sustained stress.

Hydraulic wet brakes distribute braking force across multiple friction discs, spreading heat and wear over larger surface areas. Even force distribution prevents hot spots that cause warping or cracking in single-surface brake designs.

Ausco Brakes: Maintenance Tips

Monitor Oil Levels and Quality

Check brake oil levels weekly during pre-operation inspections. Low oil levels indicate leaks or excessive consumption that require immediate attention. Examine oil color and consistency monthly.

Clean oil appears amber or light brown. Dark, cloudy, or gritty oil signals contamination or breakdown. Replace oil according to manufacturer intervals, typically every 1,000 to 2,000 operating hours. Use only specified hydraulic brake fluid to maintain system integrity. Mixing incompatible fluids can cause seal damage and reduced braking performance.

Inspect Seals and Connections

Examine brake housings for oil seepage around seals and gaskets. Small leaks quickly become major problems if left unaddressed. Replace worn seals during scheduled maintenance to prevent contamination and fluid loss.

Check hydraulic line connections for tightness. Vibration can loosen fittings over time, creating leak points. Torque all connections to specification during routine service intervals.

Test Brake Response and Adjust as Needed

Perform brake tests in safe areas away from other equipment and personnel. Apply brakes at various speeds to verify consistent response. Uneven stopping or delayed engagement indicates adjustment or repair needs. Measure brake holding capacity on inclines.

Machines should remain stationary on maximum-rated slopes without creeping. Listen for unusual noises during braking, such as grinding and squealing. These sounds commonly point to worn friction materials or contamination in the brake assembly. Address any abnormalities before continuing operations.

Keep Your Heavy Equipment Safe and Operational

The role of hydraulic wet brakes in load-carrying equipment extends beyond simple stopping power. These systems deliver reliable performance under conditions that would cripple other brake designs. Their ability to manage heat, resist contamination, and function in harsh environments makes them indispensable for mining and industrial operations.

Bull Powertrain supplies Ausco products that withstand heavy-duty applications. Our inventory includes brake components engineered for reliability and longevity. Contact our team to discuss your equipment needs and find solutions that keep your fleet operating safely.